Tile Blades

Filters

- 2" (1)

- 2-3/8" (1)

- 3" (1)

- 3-3/8" (2)

- 4" (3)

- 4.5" (8)

- 5" (7)

- 7" (2)

- 8" (1)

- 10" (4)

- 4.5" Fine (1)

- 5" Fine (1)

- 4.5" Medium (1)

- 5" Medium (1)

- 10" (5/8", 1" Arbor) (1)

- 10" (5/8", 7/8", 1-3/16" Arbor) (3)

- 10" (5/8" Arbor) (2)

- 10" (5/8", 1" Arbor) (4)

- 10" (5/8", 20mm, 7/8" Arbor) (2)

- 4" (5/8", 20mm, 7/8" Arbor) (1)

- 4" (7/8" Arbor) (1)

- 4.5" (5/8", 7/8" Arbor) (1)

- 4.5" (5/8", 20mm, 7/8" Arbor) (4)

- 4.5" (5/8", 20mm, 7/8") (1)

- 5" (5/8", 7/8" Arbor) (1)

- 5" (5/8", 20mm, 7/8" Arbor) (5)

- 5" (5/8", 20mm, 7/8") (1)

- 6" (1" Arbor) (1)

- 7" (5/8", 7/8", 1" Arbor) (3)

- 7" (5/8", 7/8", DK Arbor) (1)

- 7" (5/8" Arbor) (1)

- 7" (5/8", 20mm, 7/8" Arbor) (4)

- 7" (5/8", 7/8" Arbor) (2)

- 7" (Diamond, 5/8", 7/8" Arbor) (1)

- 8" (5/8", 7/8", 1-3/16" Arbor) (3)

- 8" (5/8", 7/8", DK Arbor) (1)

- 8" (5/8" Arbor) (1)

- 8" (5/8", 1" Arbor) (4)

- 8" (5/8", 20mm, 7/8" Arbor) (1)

Rubi VIP Premium Wet Diamond Blades

Rubi5.0 / 5.0

2 Reviews

The VIP WET diamond blade is recommended for fast cutting of hard materials such as: granite, rustic stoneware, quartz, slate and porcelain tile....

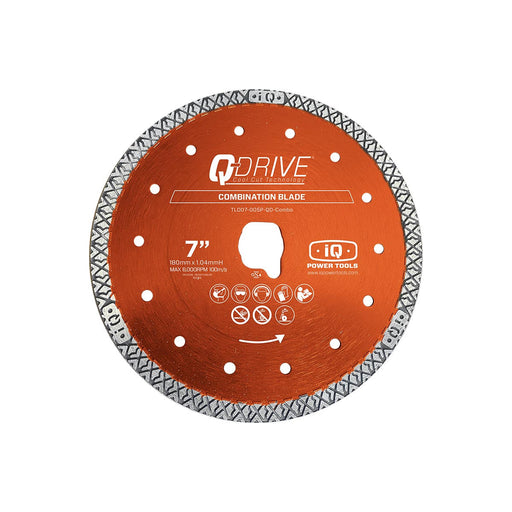

View full detailsiQ Power Tools 7" Q-Drive Combination Blade

IQ Power ToolsThe iQ Q-Drive Combination 7" Blade is a unique blend of diamond concentration, metal type, and flange thickness that cuts cool and dampens vibrati...

View full detailsMontolit Xamuray Diamond Blades

MontolitMontolit's Xamuray Tile Blade is a professional quality tile blade offering fast cuts and a long life. Great everyday blade for cutting ceramic, po...

View full detailsiQTS244 10" Q-Drive Combination Blade

IQ Power ToolsThe iQ Q-Drive Combination 10" Blade is a proprietary composition of diamond concentration, metal type, and flange thickness cuts cool while reduci...

View full detailsRubi Red Cobra Diamond Blades

RubiRubi's most premium and versatile blade, the Red Cobra is recommended for cutting all types of ceramic tiles and porcelain tiles. Additionally, the...

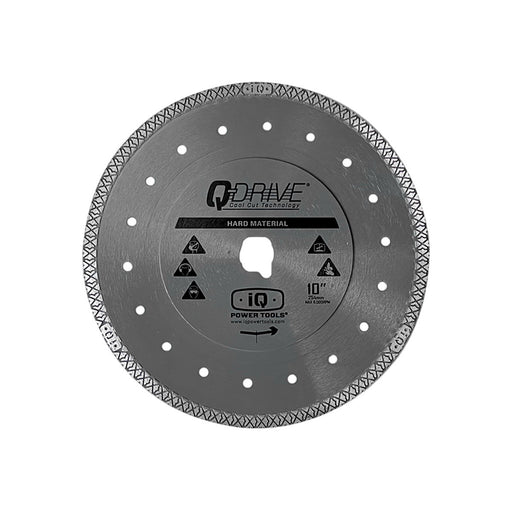

View full detailsiQTS244 10" Q-Drive Hard Material Blade

IQ Power ToolsThe Q-Drive Hard Material 10" Blade is made up of a special blend of diamond concentration, metal type, and flange thickness that cuts cool and red...

View full detailsMontolit Continuous Rim DNA Diamond Blades

MontolitPremium Montolit quality blade designed for long life and clean cuts! Main Feature: double layer sandwich diamond blade wet cut the main cutting ed...

View full detailsMontolit Tutorcut Grinder Blade Guide

MontolitThe TUTORCUT from Montolit allows straight and perfect cuts while cutting with a grinder. The TUTORCUT tool is able to keep the blade on the same l...

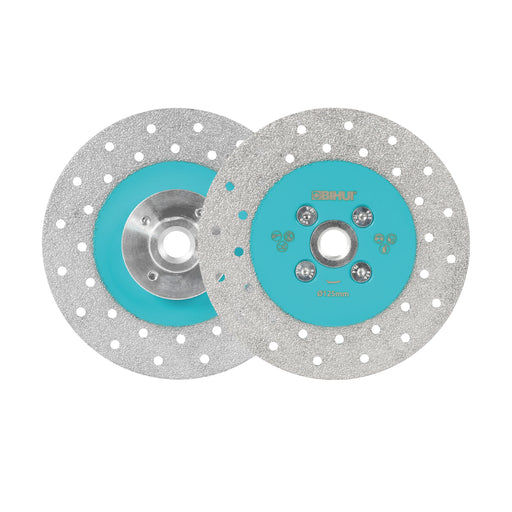

View full detailsBihui 5" Edge Cutting and Grinding Blade

BIHUIThe Bihui 5" Edge Cutting and Grinding Blades shines while creating long miters for seamless outside corners. This rigid blade is manufactured wit...

View full detailsRTC Rockin Red Dressing Stone for Diamond Blades

RTCNews Flash: Diamond Blades and Bits ain’t cheap! Protect your investment and maximize your Diamond Blade’s lifespan and cutting quality by redressi...

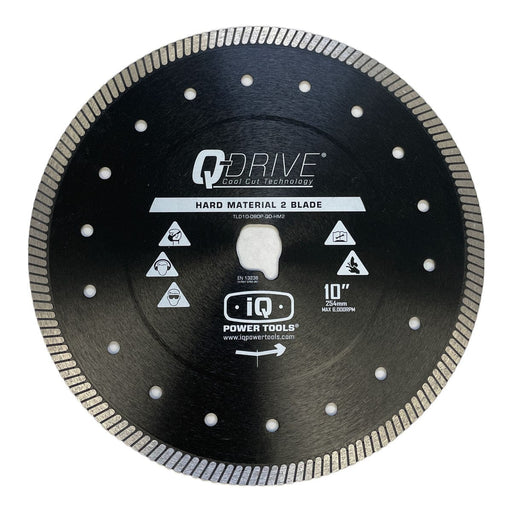

View full detailsiQTS244 10" Turbo Cutter Blade for Hard Material and Porcelain

IQ Power Tools10" x.060 Q-Drive Plus-Tile Blade Dry Hard Material Blade This state-of-the-art blade has been designed to tackle the most challenging materials in...

View full detailsZenesis Glass Tile Blade

HelixFor cutting glass tile (wet only) the Zenesis Glass tile blade features Zenesis engineered diamond placement technology, ensuring smooth chip-free ...

View full detailsMontolit Jollymont Mitering Diamond Blade

MontolitAlternating continuous band “turbo” sintered discsUsage: dry and wetMaterials: porcelain Stoneware, thick porcelain tiles, granite, marble, klinker...

View full detailsBihui Tools 4.5" Diamond Cutting and Grinding Wheel

BIHUIInnovative multi-purpose diamond cutting and grinding cup Designed for finishing tiles: bevelling, small cuts, grinding, rounding and shaping edge...

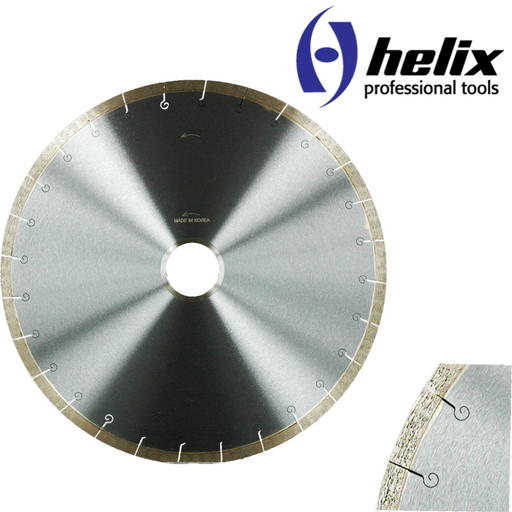

View full detailsHelix ARIX 10" Porcelain Tile and Paver Blade

HelixThe ARIX diamond blade provides faster cutting speeds and longer blade life because of precise diamond arrangement throughout each segment. In fiel...

View full detailsHelix Diamond Dressing Stone

HelixSave money and stop throwing away diamond tools with useful life in them! Helix dressing stones are made to sharpen and re-expose diamond particle...

View full detailsRTC T3 Xtreme Razor Blades

RTCSilent, Precise, Fast: The T3 Xtreme Advantage for Tile Contractors Enhance your craftsmanship with the T3 Xtreme Triple Threat diamond blade, craf...

View full detailsRTC Glass Master Laser Series

RTC5.0 / 5.0

1 Review

The all new RTC Glass Master Laser Series is one of the thinnest, fastest and smoothest cutting glass blades available today. By making improvemen...

View full detailsiQMS362 16.5" Q-Drive Segmented Combo Blade

IQ Power ToolsBlack 16.5 inch arrayed segmented diamond blade with Q-Drive® arbor used to a range of materials like brick, concrete and soft pavers. Blade Featur...

View full detailsHelix Hellion 5" Contour Diamond Blade

HelixFor radius cutting of marble – the Helix Diamond Contour blade will perform fast, chip-free radius cuts on all marbles. For radius cutting only. M...

View full detailsSigma 4-1/2" Turbo Rim Blade 75B

SigmaFeatures: Recommended for 36A3 simple bevel machine. For use on porcelain tiles and or most other materials that can be applied for dry cutting Bl...

View full detailsHelix Mini Hellion Mitering Blade

HelixFeatures & Applications: Usage: Suitable for both dry and wet cutting. Compatible Materials: Porcelain (including thick porcelain tiles) G...

View full detailsDewalt XP4 10" Premium Wet Tile Blade

DewaltPacked with a premium XP4 cutting matrix, which provides 4 times the life of standard blades, DEWALT XP4 Tile Blades offer long life and optimum cu...

View full detailsBihui Tools 5" Metal Master Blade

BIHUIThe Bihui Tools Metal Master is suitable for cutting various building material such as aluminum, steel pipe, steel sheet, angle iron, PVC pipe and ...

View full detailsGetting the perfect cut on tile requires the right blade for the job. Every material, from porcelain to glass, requires a specialized blade that will cut tile without chipping and/or breaking it. Cutting tiles correctly is an essential step in the tile installation process, and a simple misstep or an incorrect tool can damage the tiles and compromise the quality of your work.

Tile ProSource offers a premium selection of tile blades that can handle the demands of current design trends and deliver smooth and precise cuts on even the most difficult materials.

Tile Blades You Can Rely On

Tile blades are not created equal — even built from the same material and having the same slot shape, higher quality tile blades are available that outperform “me too” products. Blades perform different tasks, such as cutting glass while eliminating chips, or chewing through exterior porcelain pavers without burning up the saw. We're committed to offering the best quality tile blades from top industry manufacturers, like Montolit, Pearl Abrasive, Helix and more.

Our collection includes:

Porcelain Blades

Porcelain tile is fired at a higher temperature during the manufacturing process. Because of this, porcelain is a hard material and difficult to cut. Certain blades are able to handle the work load and repeated use because of their specialty slot shapes and diamond placement.

Grinder Blades

Most projects will require difficult cuts. This can be notching tile to accommodate a wall outlet or cutting a hole dead center of the tile to cover a plumbing fitting. Grinder blades are offered in a variety of sizes, including multiple arbor sizes to fit multiple brands of grinders, and blade sizes to accommodate different depths of cuts. Depending on the workload the blade will need to handle, blades can be purchased for a higher value and longer life.

Glass Blades

Glass-cutting blades have a fine diamond-coated edge that can cut delicate items like glass tiles and mosaics without chipping them. They provide an unblemished edge required for quality glass tile installations.

Tile Saw Blade FAQs

Some common questions concerning tile saw blades include the following:

How Long Will a Tile Saw Blade Last?

A quality diamond blade can last a long time if you care for it properly. This includes storage while not using, reviving as needed with a dressing stone and using directed water when necessary to prevent overheating. Without proper care, the life span can decrease by half.

What Maintenance Is Required for Diamond Tile Blades?

To keep your blade performing at its best, dress the blade using a quality dressing stone to maintain sharpness, only use it for cutting tile materials that are suited to it’s design, and invest in a blade storage box to prevent blades from rattling loose in a toolbox, which can cause dents and dings which decrease the quality of cuts.

Shop Quality Tile Cutting Blades

Tile ProSource is dedicated to supplying the highest-quality diamond tile blades that help tile professionals and contractors work faster and more accurately. Enjoy free shipping on orders over